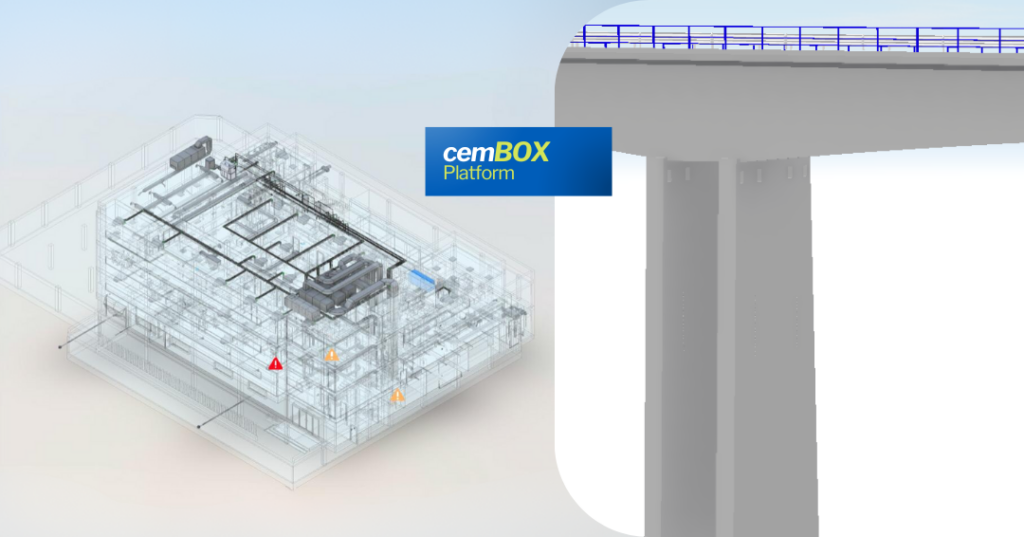

CEMBOX is an advanced digital twin platform classified as level four according to AUTODESK standards. It integrates static information (e.g., BIM models), dynamic data (e.g., real-time monitoring) along with data processing to conduct real-time analysis or simulate scenarios with high accuracy. It features a user-friendly, intuitive interface (including 3D visualization), making it ideal for decision-making and the efficient management of buildings and infrastructures (such as roads, railways, dams…).

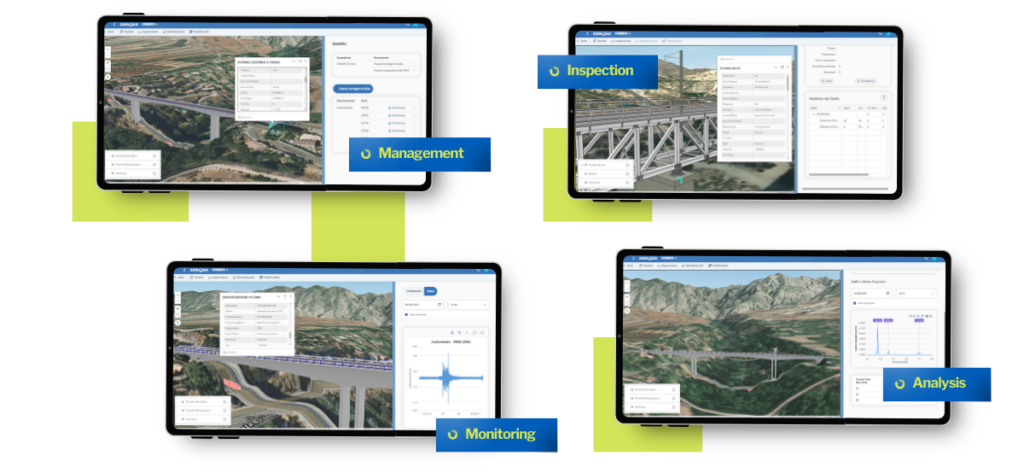

CEMBOX Infra is an asset management platform for civil infrastructures based on digital twins enabling the interaction with static and dynamic data and providing: Visualisation, Prediction and Simulations.

CEMBOX Building is a virtual replica of a built asset (building) that includes static data (BIM models), dynamic data (real time monitoring data), indicators (data processing), and scenario simulations (energy performance models).

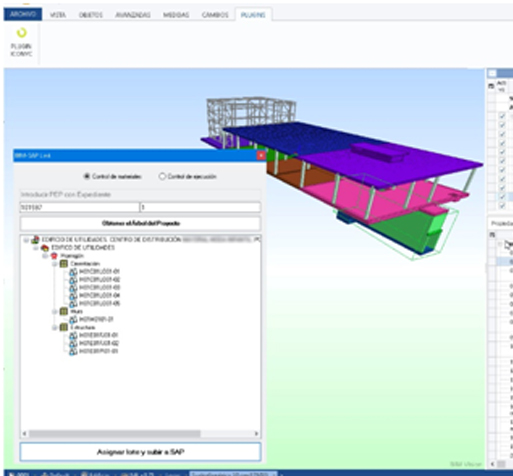

CEMOSA adapts its processes for Materials Control and Geotechnical Characterisation to the BIM methodology, developing its own BIM software integrated in its SAP-ERP business management platform, thus becoming one of the first companies to adopt this methodology in these areas.

The software makes to carry out all the necessary tasks in the geotechnical characterisation process: from boreholes planning and obtaining the corresponding BIM model to entering data from on-site field work, generating boreholes reports, defining geotechnical units or obtaining BIM models of real boreholes and geotechnical units.

Regarding the Materials Control, the software covers all activities, from planning (control batches, material samples, tests…), the taking of samples and on-site tests through mobile devices connected in real time to the SAP system, the entry of results and the generation of reports, as well as the automatic generation of the BIM model with all the results of the control.

The work has been developed in the context of a R&D project called ICONYC.

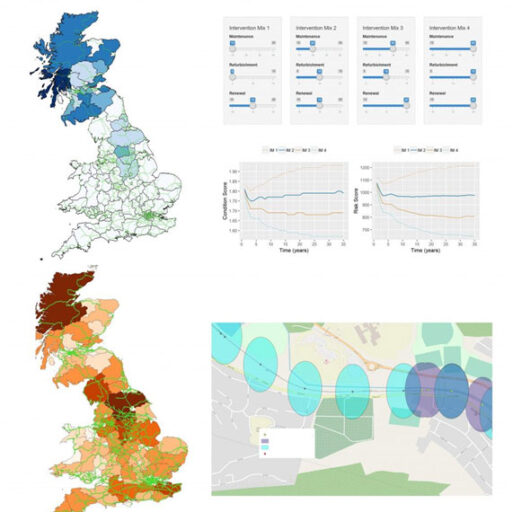

CEMOSA has developed a broad portfolio of methodologies focused on the study of earthworks using data analytics techniques in order to keep evolving in one of its key business areas.

The overall objective of this study is to improve different aspects of the earthworks maintenance process by applying carefully selected data mining techniques and to use the information

extracted from them to build an Intelligent Asset Management System. The different areas covered in this work are presented as follows:

• Anomaly Detection. Development of a methodology to find the track geometry conditions which act as precursors of earthworks failures or degradation.

• Process Mining. The aim of this study is to determine whether the process of earthworks surveying is biased by the time of the year in which it takes place.

• Predictive Models. This study was focused on testing the hypothesis that increased rainfall levels during winter and extreme desiccation during summer – due to climate change – will translate in the future in a faster degradation of earthworks in wetter and drier areas of Europe.

• Earthworks Asset Management at the Strategic Level. Development of a strategic Intelligent Asset Management model based on Petri Nets to investigate optimal intervention schemes so as to offset the effect of earthworks degradation under budget and resource constraints.

Network Rail, the infrastructure manager of the UK, was the main partner in the development and the validation of these technologies.

All of these technologies were performed in the context of a Research and Innovation project called IN2SMART.

CEMOSA has developed and released an innovative software for the designing of pavement which includes all the processes and calculations in a single tool.

This software incorporates a number of modules which allow the designer to integrate in a single multi-device web application the whole process of calculation and designing of any typology of bitumen pavement along with the generation of a final report. The app includes traditional bitumen mixes together with a number of recycled bitumen mixes developed during REPARA 2.0. Project.

The application was developed in the context of a R&D project called REPARA2.0.

Currently, there are two main ways of designing the track in railway infrastructures, the track ballast and the slab track systems.

CEMOSA has been involved in several Research Project related to the development of slab track systems in order to ease the transition from the traditional ballast track towards slab track.

- Device for securing a sleeper. Patent PCT/ES2017/070140.

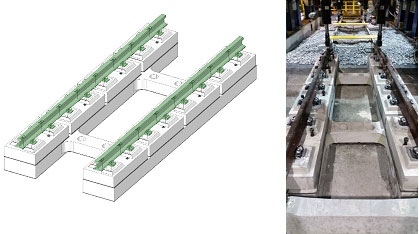

In the CAPACITY4RAIL project (within the 7th Framework Programme), CEMOSA together with other European partners has developed an innovative slab track system called 3MB (Moulded Modular Multi-blocks slab track).

- Instalación para vías férreas con placas prefabricadas y procedimiento automatizado de montaje de la misma. National Patent P201930613

In collaboration with the Polytechnic University of Valencia, Eurecat Tecnological Center, the construction company VIAS and the railway manager of the Generalidad of Cataluña, CEMOSA has developed a new slab track system, called Robotrack. This development has been done during the Research Project Robotrack.

- Slab track system – Fastrack

CEMOSA has collaborated in the development of an innovative slab track system called Fastrack. The design has restricted to a number of technical requirements with the objective of streghtening the benefits of these systems and addressing some of its weaknesses.

CEMOSA has developed an innovative high-performance system to determine the permeability and the Surface defects in pavements, oriented to the automation of the process of measurements.

The equipment, patented under P201430936, consists of a trailer equipped with a water tank, a pump, and a number of water nozzles which simulates an amount of standardised rainfall on the pavement. By the use of a termographic camera strategically located is possible to determine the drainability of the pavement for a given rainfall.

This equipment was developed in the context of following R&D projects: PAVISOST, REPARA2.0 and INFRAADAPT.

Bitumen mixes present water drain issues when the roads have low longitudinal slopes or changes in cant. In these cases, the usual solution adopted is rain hazard signalling, slippery

pavement. In addition, there are not standardised tests for the simulation of rainfall and the determination of the clean capacity in pavements.

For that reason, CEMOSA has developed a new test equipment for the determination of main features of pervious pavements: permeability rate, durability and performance in case of rainfall. The need of this device appears from the low accuracy of the current methods to determine these parameters and the lack of prescriptions.

The developed equipment allows the performance of several tests directly on the bitumen mix sample made for other test equipment such as the plate compactor, offering an accuracy and reliability notably higher than the current methods.

The equipment was developed in the context of a R&D project called PAVISOST.